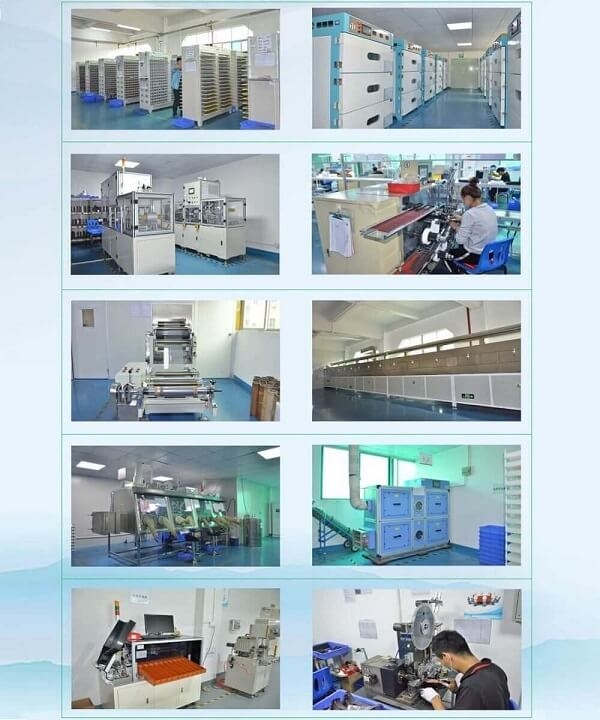

If you want to guarantee the product quality of lithium battery cells, you must ensure that the production equipment for producing lithium battery cells runs well.

There are many steps in the production of lithium battery cells, and there are many production-related equipment. Here we will introduce the main steps and equipment of the cell production process:

The main production steps of lithium battery cells

Pulping

A special solvent and binder for pulping are mixed with the powdery positive and negative electrode active materials, and evenly mixed at a high speed to make a slurry-like positive and negative electrode materials.

Coating

The coating film uniformly coats the prepared slurry on the surface of the metal foil and dries to form positive and negative pole pieces.

Assembly

The assembly is placed in the order of the positive electrode sheet-separator-negative electrode sheet-separator from top to bottom, wound to make the battery core, and then injected into the electrolyte, sealing and other processes to complete the battery assembly process. Finished battery.

Formation detection

Uses special battery charging and discharging equipment to perform charge and discharge tests on the finished batteries, and tests each battery to select qualified finished batteries for delivery.

As there are many production equipments needed in the cell production step, the following highlights some important production equipments.

The main production equipment of lithium battery cells

Coating machine

The coating machine is specially used for coating the positive and negative electrodes of lithium battery cells, and is coated on aluminum foil and copper foil. The high-end coating machine has the advantages of extrusion die mode and continuous coating, which can provide better coating effect.

Winding machine

The winding machine is mainly used for winding the lithium battery pack cells, and is suitable for pole pieces and various separators. A good winding machine can automatically wind, automatically change the needle, automatically stick the end tape and automatically cut the material, the operation is simple and the efficiency is high.

Heating shaping machine

The heating shaping machine is also specially applied to the electric core. The heating plate adopts brass plate, which has good thermal conductivity, safety and environmental protection.

Sealer

The sealing welding machine is a plastic welding machine designed for welding lithium battery cells or large and irregularly shaped thermoplastic workpieces. It is a highly reliable and very durable plastic welding machine. It has fast setting, quick mold change, simple and intuitive program control and extremely high safety features.

The production steps of lithium battery cells are actually relatively cumbersome, and the content of the production steps in the article is only a brief overview. The application range of lithium battery cells is also relatively common, so the safety issues of lithium battery cells are also worthy of attention. Not only should we pay attention to whether there are problems in the production process, but also to pay attention to whether the production equipment is stable.