First, natural beauty

Lithium was discovered in 1817 by the student of the Swedish chemist Bezilius, Alfetson, who named it Lithium. By 1950, Nakamoto and Maggien used the method of electrolytic melting of lithium chloride to obtain metal lithium, and industrial lithium was proposed by Gensa in 1893. Lithium is still produced by electrolytic LiCl. This method consumes a large amount of electric energy, and consumes 6,000 to 70,000 kWh per ton of lithium.

Lithium has served the medical profession primarily as an anti-gout drug for more than 100 years after his birth. The National Aeronautics and Space Administration (NASA) first recognized that lithium batteries can be used as an efficient battery. This is because the battery voltage is closely related to the activity of the negative electrode metal. As a very active alkali metal, lithium batteries can provide higher voltages. For example, a lithium battery can provide a voltage of 3V, while a lead battery has only 2.1V, while a carbon zinc battery has only 1.5V. According to P=UI, the lithium battery can output higher power at the same current.

As element No. 3, lithium existing in nature consists of two stable isotopes, 6Li and 7Li, so the relative atomic mass of lithium is only 6.9. This means that metal lithium provides more electrons than other reactive metals at the same mass. In addition, lithium has another advantage. Since the lithium ion has a small ionic radius, lithium ions are more likely to move in the electrolyte than other large ions, and an effective and rapid migration between the positive and negative electrodes can be achieved during charge and discharge, thereby allowing the entire electrochemical reaction to proceed.

Metal lithium has many advantages, but there are still many difficulties to overcome in manufacturing lithium batteries. First, lithium is a very active alkali metal element that reacts with water and oxygen, and it reacts with nitrogen at room temperature. This results in the storage, use or processing of metallic lithium being much more complicated than other metals, and the environmental requirements are very high. Therefore, lithium batteries have not been used for a long time. With the research of scientists, the technical obstacles of lithium batteries have been broken one by one, lithium batteries have gradually entered the stage, and lithium batteries have entered a large-scale practical stage.

Second, the metal lithium battery

In the development of metal lithium primary batteries, the electrochemical properties of conventional cathode materials such as Ag, Cu, and Ni have not been met, and people have to find new cathode materials. In 1970, Sanyo Corporation of Japan used manganese dioxide as a positive electrode material to create the first commercial lithium battery. In 1973, Panasonic began mass production of a lithium primary battery with a positive electrode active material of a fluorinated carbon material as a positive electrode. In 1976, a lithium iodine primary battery with iodine as its positive electrode was introduced. After the 1980s, the cost of lithium mining was greatly reduced, and lithium batteries began to be commercialized.

Early metal lithium batteries were primary batteries that could only be used once and could not be charged. The success of lithium batteries has greatly stimulated the enthusiasm of people to continue to develop rechargeable batteries, and the prelude to the development of lithium rechargeable batteries has been opened. In 1972, Exxon developed titanium disulfide as the cathode material and lithium metal as the anode material to develop the world's first lithium metal rechargeable battery. This rechargeable lithium battery has excellent performance for deep charge and discharge of 1000 times and no loss of more than 0.05% per cycle.

Lithium rechargeable batteries have been studied very deeply, but until now, rechargeable batteries with lithium metal as the negative electrode have not been commercialized. This is because lithium rechargeable batteries have not solved the safety problem of charging. When the lithium battery is charged, lithium ions obtain electron precipitation metal lithium at the cathode. In an ideal state, metallic lithium should be poured on the ground (electrode) like water (metal lithium) and laid a flat layer. However, the deposition of metallic lithium on the cathode, like a tree growing on the ground, forms a dendritic structure. These dendritic lithium metal is charged and discharged several times, and when the length of the branch is large enough, it can be connected from the positive electrode to the negative electrode, causing a short circuit inside the battery, which may cause the battery to ignite or explode. After 1989, most companies stopped developing lithium secondary batteries.

Third, rocking chair battery

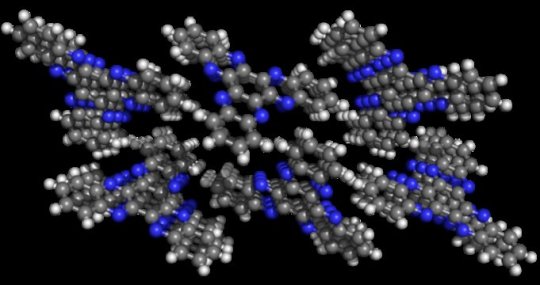

In order to circumvent the problem of dendritic crystals generated during the precipitation of metallic lithium, in 1980, Armand first proposed the concept of RCB. The metal poles are no longer using metallic lithium, but a lithium-based chimera. In the lithium chimera, there are three-dimensional or two-dimensional voids in the chimera, and metallic lithium is not present in a crystal form but in the form of lithium ions and electrons in the voids. Think of a lithium chimney as a hamburger. The chimera is equivalent to two slices of bread, and the lithium atom (lithium ion and electron) is the middle steak that can be easily extracted and added. For this reason, lithium ion interns can replace lithium metal as a supplier of lithium ions in batteries. Since lithium ions are placed in the voids of the chimera, the dendrite problem is no longer serious. More importantly, chimeras are often insensitive to air and the like. Therefore, the lithium chimera greatly increases the safety of the lithium battery.

The first embedded substance is that we are familiar with graphite. As we all know, graphite has a layered structure with a layer spacing of 0.355 nm and a lithium ion of only 0.07 nm, so lithium ions are easily inserted into the graphite to form a graphite lithium chimera having a composition of C?Li. In 1982, R.R. Agarwal and J.R. Selman of the Illinois Institute of Technology in the United States discovered that lithium ions have the property of being embedded in graphite. They found that the process of lithium ion intercalation into graphite is not only fast. At the time of charging, the graphite electrode receives electrons and is intercalated with Li+ ions to form a graphite-lithium compound having a reaction formula of C?+Li?+e?→C?Li. When discharged, the reverse reaction of the above process occurs.

Therefore, the improved lithium battery is capable of releasing or storing energy because lithium ions repeatedly travel between the two electrodes. During charging, the current drives out the lithium ions in the positive electrode fitting, and these lithium ions "swim" through the electrolyte between the positive electrode and the negative electrode into the negative electrode fitting; while discharging, the lithium ions are embedded from the negative electrode. The compound "swim" back into the positive electrode assembly through the electrolyte. Lithium maintains a stable ionic form throughout the detachment and embedding cycle. Lithium ions can oscillate at the bipolar junctions of the battery, hence the name "Rocking Chair Battery" (RCB).

Fourth, lithium ion battery

Graphite is inexpensive and structurally stable. It is an ideal anode material, so what material should be used for the positive electrode? In 1970, M.S. Whittingham discovered that lithium ions can be reversibly embedded in the layered material TiS2, which is suitable for lithium battery anodes. In 1980, American physics professor John Goodenough found the new substance LiCoO2. This material also has a layered structure similar to graphite. In 1982, Goodenough discovered LiMn2O4 with three-dimensional voids that provide a three-dimensional channel for lithium ion mobility. In 1996, Goodenough discovered LiFePO? with an olive tree structure. This material has higher safety, especially high temperature resistance, and its overcharge resistance is far superior to that of traditional lithium ion battery materials.

Sony Corporation of Japan has developed a new rechargeable lithium battery in 1990, combining lithium cobalt oxide (positive electrode material) and graphite (negative electrode material) and using an organic solvent containing a lithium salt (such as lithium hexafluorophosphate) as an electrolyte. This type of battery is commercialized. Such a battery can work at voltages above 3.7 volts, and Sony has renamed the technology "Li-ion." This logo can be found on many mobile phone batteries or laptop batteries. High performance, low cost, and good safety. This lithium-ion battery was immediately welcomed as soon as it was introduced, helping Sony to become the industry leader. Since the lithium ion battery does not contain heavy metal chromium, it greatly reduces environmental pollution compared with the nickel chromium battery.

The main structure of a typical battery includes three elements: a positive electrode, a negative electrode, and an electrolyte. The next important update for lithium-ion batteries is that polymer materials primarily replace electrolyte solutions. In 1973, Wright et al. found that certain polymers were able to conduct lithium ions faster. In 1975, Feullade and Perche discovered that the alkali metal salt complexes of PEO, PAN, PVDF and other polymers have ionic conductivity. In 1978, Dr. Armadnd of France predicted that such materials could be used as electrolytes for energy storage batteries, and the idea of solid electrolytes for batteries was proposed. In 1995, Sony Corporation of Japan invented a polymer lithium battery, and the electrolyte was a gel polymer. In 1999, polymer lithium ion batteries were commercialized.

Fifth, the future of lithium batteries

In 1958, Harris considered the reaction of lithium with water and air, and proposed the use of organic electrolytes as electrolytes for lithium metal batteries. This concept has always influenced the development of lithium-ion batteries. However, liquid electrolytes have certain safety hazards, so many scientific research institutions and enterprises have decided to develop new ways to develop solid electrolyte technology. The all-solid battery replaces the original liquid organic electrolytic cell with a new solid electrolyte. The solid electrolyte not only ensures the original storage performance, but also prevents dendrite problems, and is safer and cheaper.

Lithium metal batteries are another focus of scientific research in recent years. This is because the lithium chimera solves the safety problem such as dendrite, but since the chimera does not have the function of losing electrons, the battery capacity is greatly reduced. For example, the specific capacity of the metal lithium negative electrode of the battery is 11 times or more of the graphite lithium compound C6Li negative electrode! If the lithium metal rechargeable battery can be successfully developed, our electronic equipment will be lighter, and the electric vehicle will run even further!

At present, there are still some safety problems in lithium batteries. For example, some mobile phone manufacturers have poor control over the quality of diaphragm materials or process defects, resulting in partial thinning of the diaphragm, which cannot effectively isolate the positive and negative electrodes, thus causing battery safety problems. Secondly, the lithium battery is prone to short circuit during charging. Although most lithium-ion batteries now have anti-short-circuit protection circuits and explosion-proof lines, in many cases, this protection circuit does not necessarily work under various conditions, and the explosion-proof line can play a limited role. . Therefore, improving the safety of lithium batteries is also the focus of research.

BENZO Energy / UFine Technology Co.,Ltd is a high-tech enterprise specializing in Researching and manufacturing of polymer li-ion batteries.

The polymer li-ion batteries produced in our company have such advantages as high safety, high capacity, long cycle life, small volume, ultra-thin flexible design, excellent performance of charge/discharge at high rates, which can conform to CE, UN,UL and ROHS standards and can be used in mobile phones, bluetooth, MID, portable DVD, MP3 / MP4, digital camera, electric toys and tools, energy storage equipment, electric-bike, GPS, miner lamp, LED lamps, medical devices and so on.