At present, whether the battery is a lithium iron phosphate battery, a ternary battery, or a lithium titanate battery can not be separated from the battery protection circuit board, someone asked why use a protection board? Wouldn't it save a lot of money not to use a protective plate? Customers who think this way are not surprised, because they do not understand lithium batteries, do not understand the characteristics of the battery, if you understand the lithium battery, you will feel that this money can not be saved, this is the last line of defense to ensure the safety of battery products.

Lithium batteries have developed rapidly in recent years. Although they have been developed for nearly a hundred years, there are currently no materials that can guarantee that the batteries will not ignite and not explode. All need to add a protection board to protect the battery from overcharging, overdischarging, overcurrent, and short circuits To achieve battery safety, why are lithium batteries so afraid of overcharging and overdischarging? The reason is that in the overcharged state, the energy will be excessive after the battery temperature rises, so the electrolyte decomposes to generate gas, and there is a danger of spontaneous combustion or rupture due to the increase of the internal pressure; on the contrary, in the overdischarged state, the electrolyte causes the battery to decompose due to decomposition. Deterioration in characteristics and durability reduces the number of recharges. The protection circuit of the lithium-ion battery is to ensure the safety in such an overcharged and discharged state, and to prevent the characteristics from being deteriorated.

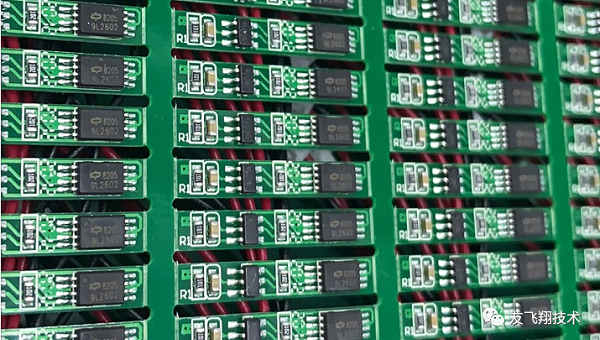

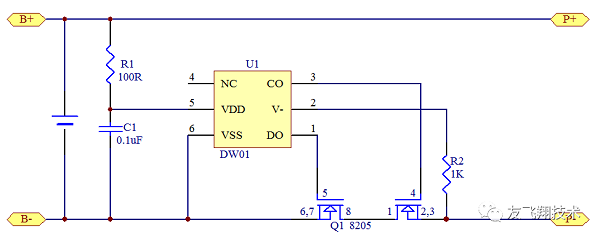

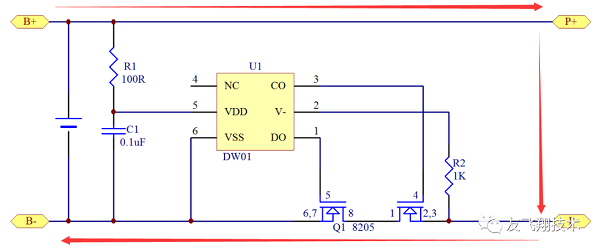

The protection circuit of the lithium-ion battery is composed of a protection IC and two power MOSs. The protection IC monitors the battery voltage and cuts off the external power MOS to protect the battery when there is over-charge and over-discharge. Charge protection, over-discharge protection and over-current and short-circuit protection (as shown in Figure 1).

(Figure 1)

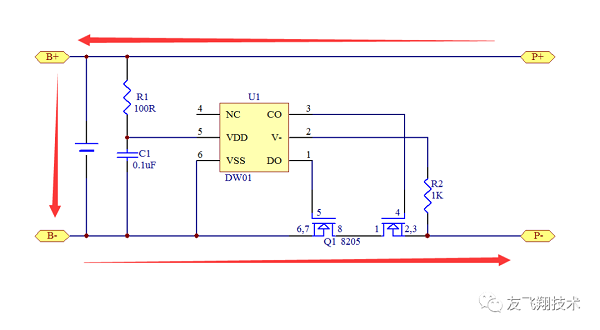

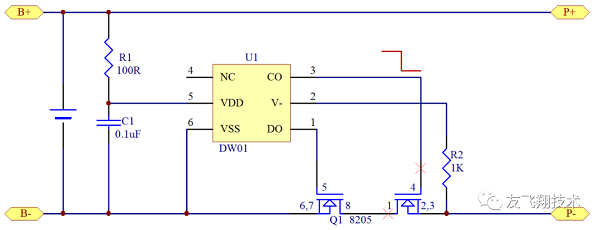

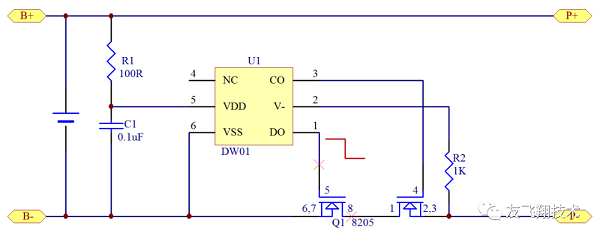

Overcharge protection: When the charger recharges the battery, the charging current flows from P + B + B- P- (as shown in Figure 2). The IC has been detecting the battery voltage. When the battery voltage rises to 4.28V ± For 120ms at 50mV, the control IC will output a low level at the CO port. Under normal circumstances, the CO port outputs a high level, and the high level becomes low to turn off the MOS and cut off the charging circuit to prevent the battery from continuing. Charging (as shown in Figure 3). After the circuit is cut off, because the charging is floating, the battery voltage will drop when there is no charging current. When the load is discharged, the battery voltage drops to the overcharge recovery voltage of 4.08V. At ± 50mV, CO will output a high level and turn on the charging MOS tube. If the charger can be recharged at this time, some people may have some questions? Did n’t you just say that the charging MOS tube is off? How can I discharge even if the circuit has been cut off? In fact, this is a problem of the internal structure of the MOS tube. There are individual diodes in the MOS. The direction of the diode is opposite to the conduction direction of the MOS tube. At the same time, the current of the discharging circuit and the charging circuit is opposite. When discharging, the current flows from the charging MOS. The body diode of the tube flows through, so that it can continue to discharge after overcharging, but the design must deal with this problem, because the current flowing through the body diode is limited, and it cannot be discharged at high current for a long time. Otherwise, the charging MOS tube will be burned out, so the battery capacity, load capacity, and voltage protection and recovery parameters of the IC must be considered when designing the protection board of the battery. Otherwise, it may easily cause design defects, product failure, and potential safety hazards.

(Figure 2)

(Figure 3)

Over-discharge protection: When the battery powers the device, the discharge current flows from B + P + P- B- (as shown in Figure 4). The IC will always detect the battery voltage during the discharge process. When the battery voltage drops to 2.4V When ± 100mV lasts for more than 60ms, the control IC will output a low level at the DO port. Under normal circumstances, the DO port outputs a high level, and the high level becomes low to turn off the MOS and cut off the discharge circuit to prevent The battery continues to discharge (as shown in Figure 5). After the circuit is cut off, the battery voltage will rise after there is no discharge current. When the charger is connected or the battery voltage rises to the over-discharge recovery voltage 3.0V ± 100mV, DO will output a high Level, turn on the discharge MOS tube, why can the charger be connected after the discharge MOS is turned off. The principle is the same as the above charge MOS. The charging current and the discharge current are opposite, and the current passes through the body diode inside the MOS tube. So it can be charged.

(Figure 4)

(Figure 5)

Over-current and short-circuit protection: The significance of over-current and short-circuit protection is to protect the battery from high-current discharge. Large-current discharge easily damages the internal structure of the battery cell. Therefore, when a high-current discharge occurs, the discharge circuit must be cut off, which protects the battery and the PCB circuit. Short-circuit is also a kind of high-current discharge. When customers use improperly or the main control board fails, high-current and short-circuit conditions occur. The protection board can cut off the circuit in time to ensure that the product is in a safe range of use. The principle of protection is that the IC has a fixed overcurrent detection voltage of 0.15V and a short-circuit protection voltage of 1.3V. When the current flows through the MOS, the MOS tube has an impedance, and a voltage drop occurs across the MOS tube. The larger the current, the voltage drop The larger, calculated according to U = I * R, for example, the current flowing through the MOS tube is 5A, and the impedance of the MOS tube is 50mR, then the voltage drop generated by the MOS is 0.25mV, and there is a comparator inside the IC. When the voltage is greater than the set 0.15V for more than 10ms, DO output changes from high level to low level, cut off the discharge loop.

In summary, under the current material system, the lipo battery cells cannot be separated from the protection plate. The protection plate can protect the safe operation of the battery cell. Therefore, it is not possible to save this cost and make the battery cell lose its protection function. If the fire or explodes, then the damage caused cannot be compensated by the saved money. Don't make a big mistake.