It has been half a century since the first commercial lithium battery was released by Sony in 1991. Lithium batteries are closely related to our daily life and are inseparable. They are widely used in various electronic products. In order to protect the rights and interests of consumers, the safety of products More and more attention is being paid to it; the safety of the battery bears the brunt. At present, the safety certification of lithium batteries in all countries is quite strict, and many countries are mandatory certification tests.

Lithium battery testing is generally done by looking for a qualified third-party testing agency to test the safety performance of the battery by sending samples, and can issue corresponding test reports and certificates.

At present, our company has its own laboratory. The laboratory has a full set of safety testing equipment, which can independently detect the safety performance of the battery, which provides a strong guarantee for the design and production of our batteries.

Safety testing is mainly to simulate the safety performance of the battery in some extreme cases that may be encountered during transportation or use. The corresponding standard in China is: GB 31241-2014, and its related standards are similar to IEC 62133 (IEC: International Electrotechnical Commission)

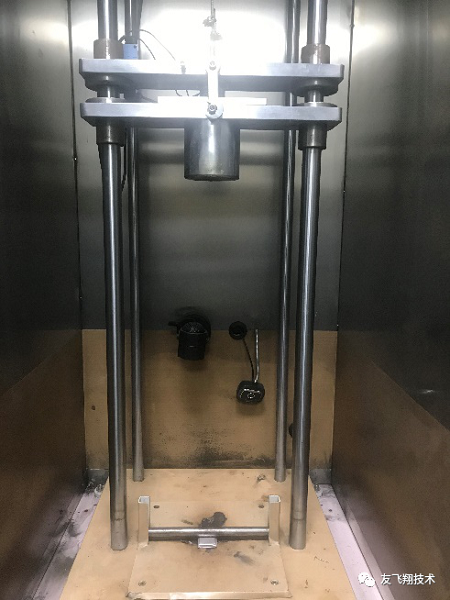

The following introduces the heavy impact test items in the safety test of lithium batteries:

1. After the battery is fully charged according to the prescribed test method, place the battery on the surface of the platform, place a metal rod with a diameter of 15.8 mm ± 0.2 mm on the upper surface of the geometric center of the battery, and use a weight of 9.1 kg ± 0.1 kg The object hit the surface of the battery on which the metal rod was placed in free fall from a height of 610 mm ± 25 mm, and observed for 6 hours.

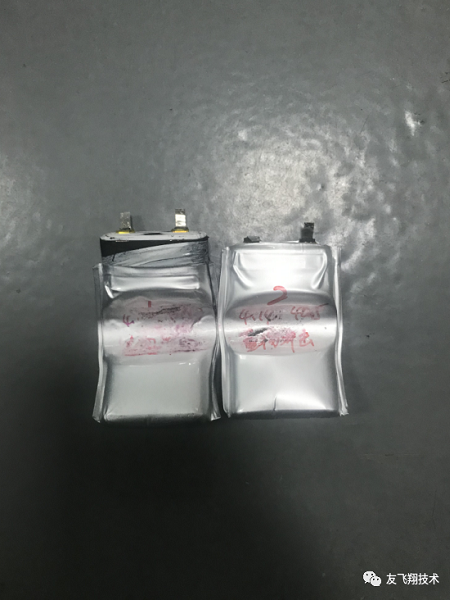

2. It is required that the battery's longitudinal axis is parallel to the plane during the impact test, and the metal rod is perpendicular to the battery's longitudinal axis. Only one impact test shall be conducted for one sample, and the battery shall not catch fire or explode.

The above tests must be completed by professionals, non-professionals do not try!

Strict selection of raw materials, mature process design, and perfect quality management system have created safe and reliable products. Our lipo batteries can pass relevant tests and have obtained corresponding certificates, such as: GB 31241-2014, IEC62133, UL1642, UL2054 in the United States , Korea KC, Japan PSE, India BIS, Taiwan BSMI, UN38.3 and so on.